The 4 forces reshaping construction in 2026 (and what to do about them)

Tariffs, talent shortages, and AI are changing everything. Here's your playbook.

👋 Hey, Kyle here! Welcome to The Influential Project Manager, a weekly newsletter covering the essentials of successful project leadership.

Today’s Overview:

Tariffs crushing margins: Material costs hit 40-year highs. Your procurement strategy just became critical.

Data centers eating talent: Hyperscale projects are pulling electricians and trades to higher-paying work.

Digital transformation accelerating: The gap between firms using AI and those resisting is widening fast.

Talent shortage worsening: 41% of workers retire by 2031. Only 7% of job seekers consider construction.

Is your schedule slipping because materials arrive late?

Most project teams aren’t failing due to execution—they’re failing because supply-chain decisions are fragmented across tools, inboxes, and disconnected spreadsheets.

Krane creates, and manages your submittals, lead times, and deliveries in one real-time workflow—giving you visibility into what’s planned, ordered, and at risk before delays strike.

✅ 10× faster supplier response times

✅ 1–2.5% less material overspend per project

✅ 7 days saved per scope in pre-con

✅ 15–20 hours/week saved for PMs and engineers

Bring predictability to procurement and delivery—See how teams use Krane!

🏗️ 2026 Engineering and Construction Industry Outlook

Filed under: Construction, Leadership, & AI

Hey there,

I just read Deloitte’s 2026 Engineering and Construction Industry Outlook, and honestly, it felt like they were describing every conversation I’ve had in the last three months.

Rising material costs. Labor shortages getting worse, not better. Clients pushing back on budgets. Everyone scrambling to figure out AI.

Sound familiar?

2026 isn’t about surviving these changes. It’s about using them to separate yourself from every other PM still playing by 2019 rules.

The construction industry is at an inflection point. The firms and project leaders who understand what’s actually happening right now will win the next decade. Everyone else will keep complaining about how hard everything has gotten.

Today, I’m breaking down the four forces reshaping our industry, what they mean for you as a project leader, and exactly what to do about them.

Let’s get into it.

Four forces changing construction

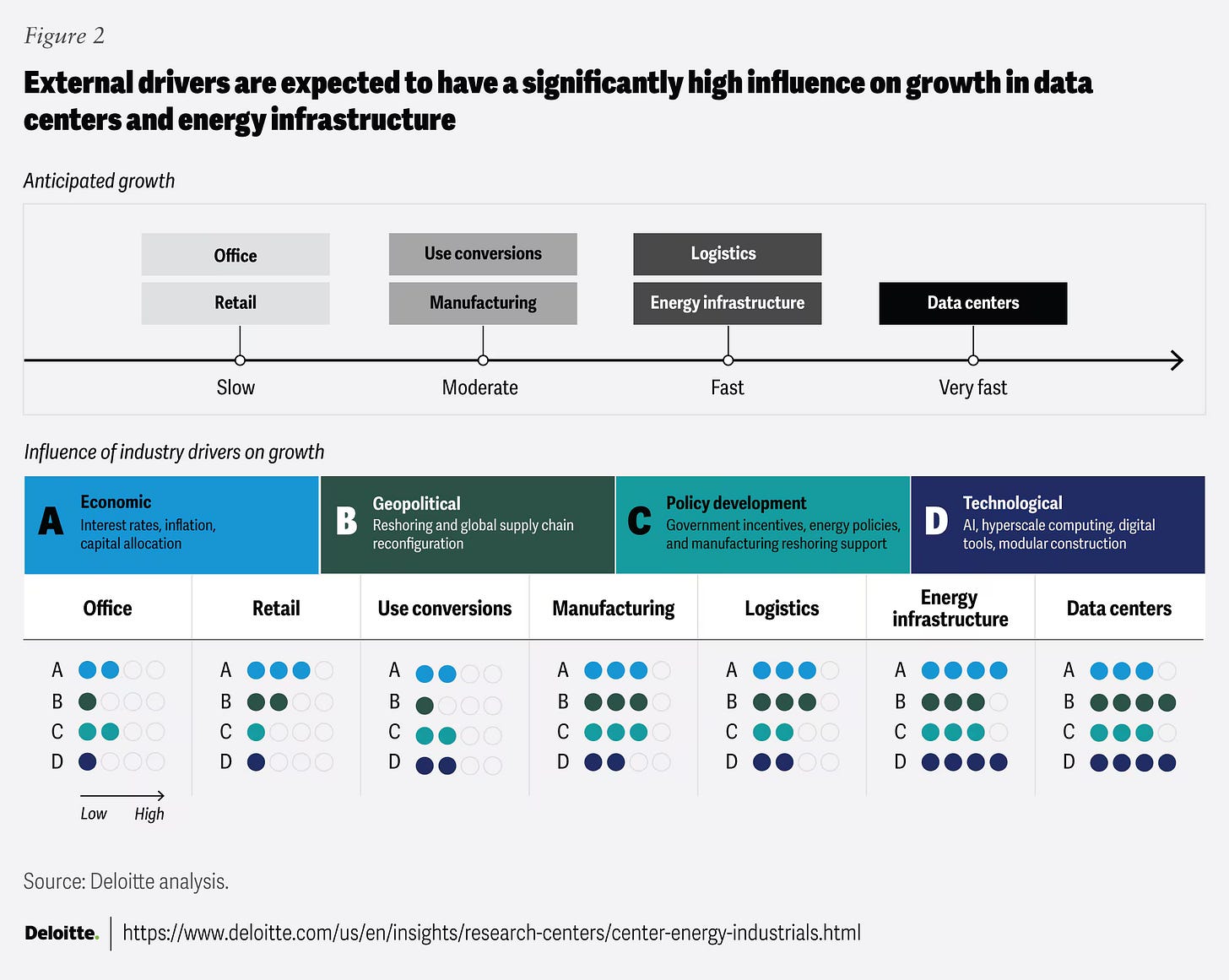

Deloitte identified four major trends hitting the construction industry in 2026. These aren’t just macro trends to be aware of. They’re operational realities you need to manage this week.

Evolving tariffs: Building resilience against supply chain disruptions and rising material costs

Shifting priorities: Growing focus on data centers and energy infrastructure to drive E&C’s next wave

Embracing digital transformation: Innovating to optimize capacity, cost, and competitiveness

Persistent talent shortage: Leveraging digital and workforce innovation to unlock opportunities

Force #1: Tariffs crushing material costs (and your margins)

The numbers are brutal.

Tariffs on steel and aluminum hit 50% in 2025. The effective tariff rate for construction goods climbed to a 40-year high of 25-30%. Material prices rose steadily from May through August 2025.

If you’re operating on already thin margins, this isn’t a minor headache. It’s an existential threat.

Here’s what’s happening on the ground: Project abandonment activity increased 88.2% year-over-year in August 2025. Developers are revisiting budgets mid-project. Clients are pushing back on change orders. If you’re locked into a fixed-price contract without escalation clauses, you’re absorbing every penny of those increases.

What this means for you:

Your procurement strategy just became one of your most important project management skills.

The best firms aren’t treating this like a temporary problem to weather. They’re building systematic approaches:

Strategic stockpiling - Buy critical materials ahead of price swings when you can predict them.

Material substitution - Work with your design team early to spec cost-effective alternatives. Have these conversations during preconstruction, not when you’re placing POs.

Supplier diversification - If you’re still relying on the same three suppliers you’ve used for a decade, you’re exposed. Build relationships now.

Contract language - Mid-market builders are incorporating tariff-adjustment or escalation clauses to pass cost increases to owners. If your contracts don’t have this protection, you need to add it yesterday.

Tie materials to your schedule - Connect procurement timelines directly to their construction schedules. When all material workflow is linked to work packages, you can see delays coming weeks earlier and adjust.

You’re a PM, not a procurement specialist. But the PMs who understand material cost volatility and can speak intelligently about mitigation strategies are the ones getting promoted to senior roles.

Your superintendent can manage the field. Can they navigate a 30% steel price increase mid-project? That’s your job now.

Force #2: Data centers and energy infrastructure eating the talent pool

Commercial construction spending declined almost 3% year-over-year in 2025. But data center construction? Exploding.

By 2035, Deloitte estimates power demand from US data centers could grow more than fivefold—from 33 gigawatts in 2024 to 176 gigawatts. AI data centers alone could grow more than thirtyfold, reaching 123 gigawatts.

Massive projects with massive budgets competing for the same electricians, welders, HVAC techs, and engineers you need for your hospital renovation or office build-out.

What this means for you:

You’re competing against hyperscale projects with deeper pockets than your client has.

If you’re managing traditional commercial work—office, retail, mixed-use—you need to get smarter about resource planning and workforce strategy.

Lock in key trades early - That electrical contractor you usually bring in during GMP? Call them during pursuit. Get them committed before the data center down the street does.

Invest in relationships - The PMs who maintain strong relationships with trade partners will get priority when labor gets tight. Pay invoices on time. Solve problems collaboratively. Don’t be the PM everyone dreads working with.

Explore prefabrication - If you can move work off-site to a controlled factory environment, you reduce your exposure to field labor shortages. Bathroom pods, mechanical racks, wall panels.

Rethink your labor model - Can you use more apprentices supervised by fewer journeymen? Can you invest in training programs that create loyalty?

The construction talent war isn’t coming. It’s here. The PMs who still think “we’ll just find someone” are about to learn a painful lesson.

Force #3: Digital transformation isn't optional anymore

Nearly half of E&C executives classify their supply chains as “fragile due to geopolitical tensions.”

The firms responding to this aren’t buying more clipboards. They’re deploying technology:

Agentic AI - Systems that autonomously manage scheduling, coordinate workflows, and flag risks before they become crises.

Computer vision for safety - Cameras that identify hazards in seconds, improving compliance and reducing incidents. Especially critical for federally funded work.

BIM and digital twins - Digital workflows that streamline project delivery, minimize rework, and can reduce timelines by up to 20%.

IoT devices - Real-time equipment tracking and predictive maintenance that minimizes downtime.

I know what you’re thinking. “Kyle, I’m still trying to get my subcontractors to use Procore instead of emailing PDFs.”

I get it. But the gap between firms embracing digital tools and those resisting is widening fast.

What this means for you:

You don’t need to become a data scientist. But you do need to become digitally literate.

Start here:

Master your project management platform - Whether it’s Procore, CMiC, or something else, know it inside and out. Use the analytics. Build the reports. Leverage the integrations. Get out of your spreadsheets!

Experiment with AI - Use ChatGPT or Claude to handle your administration. Summarize meeting notes, review change orders together, or create submittal logs. Start small. Learn what it can and can’t do. Some teams are using AI to surface procurement risks automatically—flagging vendor delays or material shortages before they hit the critical path.

Push for better data - Garbage data creates garbage insights. If your team isn’t tracking things consistently, you can’t analyze anything. Create standards. Enforce them.

Advocate for tools - If your firm isn’t investing in technology, make the business case. Show ROI. Demonstrate productivity gains.

The PMs who embrace digital tools will deliver projects faster, cheaper, and safer. Everyone else will keep drowning in admin work while wondering why they’re stuck.

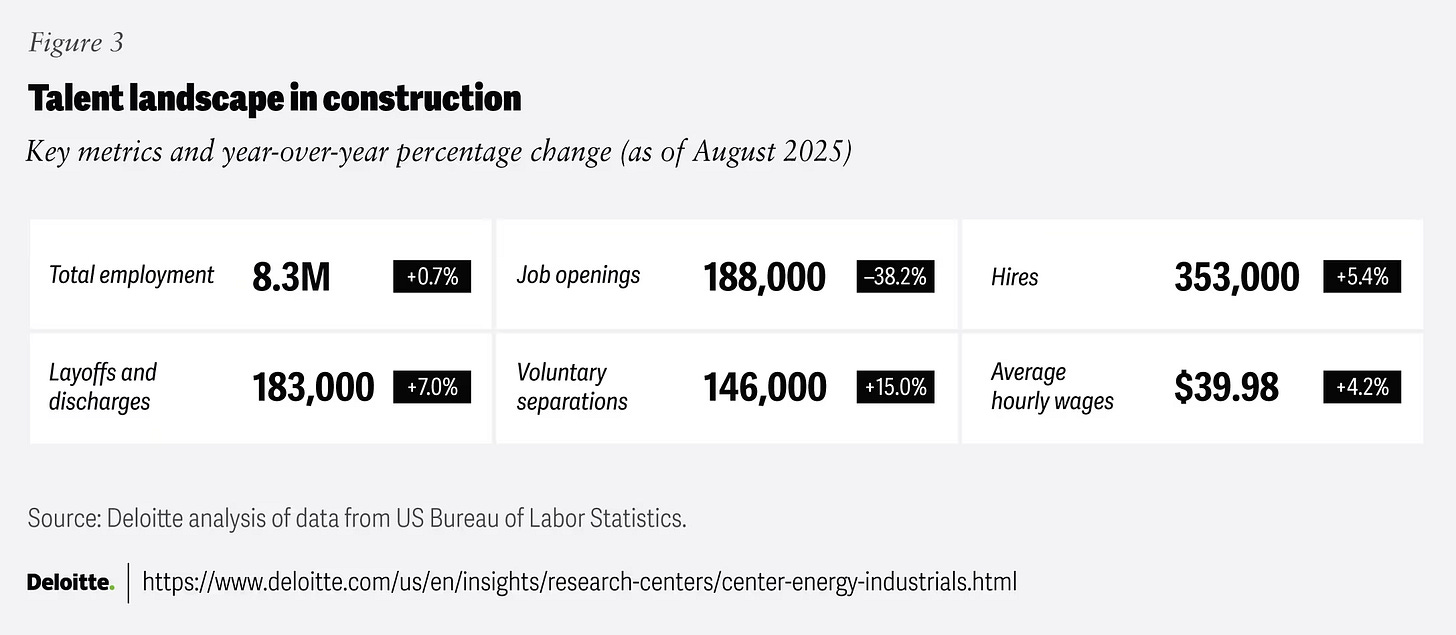

Force #4: The talent shortage getting worse (much worse)

The construction industry needs 499,000 new workers in 2026. That’s up from 439,000 in 2025.

By 2031, 41% of construction workers are expected to retire. Only 10% of current workers are under 25.

If the labor gap persists, the industry could lose nearly $124 billion in construction output due to unfilled positions.

We’re not just struggling to hire. We’re about to lose nearly half our workforce to retirement.

The surge in data centers and energy projects will pull electricians, welders, and HVAC techs to the highest-paying jobs. Projections show a potential shortage of over two million skilled craft professionals by 2028.

Only 7% of potential job seekers are even considering construction careers.

What this means for you:

Your job as a PM is evolving. You’re not just managing projects. You’re managing talent scarcity.

What works:

Become the PM people want to work for - Your reputation matters. Are you the PM who treats people with respect, solves problems collaboratively, and creates a positive culture? Or are you the PM everyone avoids?

Invest in your people - Training, mentorship, clear career paths. The firms that develop talent will retain it. The firms that treat people as interchangeable will lose them.

Leverage automation where you can - Autonomous equipment, robotics, prefabrication. Not about replacing people. About doing more with less.

Rethink recruiting - Can you partner with trade schools? Sponsor apprenticeship programs? Create pathways for people who never considered construction?

The talent shortage isn’t a problem HR solves. It’s a problem you solve every single day through how you lead, how you treat people, and how you think about workforce strategy.

Your 2026 playbook: what to do this week

Look, these four forces aren’t going away. Tariffs, shifting project types, digital transformation, and talent shortages are the new baseline.

The question isn’t whether you’ll deal with them. The question is whether you’ll lead or react.

What to do right now:

Review your contract language. Do you have escalation clauses? Tariff protection? If not, work with your legal team to update your templates before the next pursuit.

Audit your supplier relationships. Are you diversified? Do you have backup options? Build those relationships before you need them.

Block time to learn one digital tool this quarter. Pick one—AI, advanced scheduling, data analytics. Get competent. Then teach your team.

Evaluate your workforce strategy. Are you investing in people? Building a culture that retains talent? Creating career paths? If not, start.

Have the conversation with your leadership. Share what you’re seeing. Make the business case for investment in technology, training, and better contracts.

The construction industry is changing faster than it has in decades. The PMs who understand what’s happening and adapt will thrive. Everyone else will keep complaining about how hard everything has gotten.

Which one will you be?

If you want to see the full Deloitte report with all the data and charts, you can find it at Deloitte’s website. It’s worth the read.

Hit reply and let me know which of these four forces is hitting you hardest right now. I read every response.

Talk soon,

Kyle

P.S. The four forces I covered today all create one common problem: procurement chaos. Tariffs change pricing overnight. Material shortages delay schedules. Vendors miss commitments. And you’re stuck reacting instead of getting ahead of it. If you're managing complex projects where material timing matters, check out Krane. I’m piloting it on one of my projects right now.

Whenever you’re ready, here are 4 ways I can help you elevate:

Get ProjectOS. The AI-powered Notion project operating system I use to manage $300M+ in projects. Set up in 1 day, not 3 years. Save 10+ hours weekly. Most popular.

Join Antifragile Project Management. Leadership development course and community built on the 7 Archetypes Framework. Transform from project witness to project leader. Earn promotions and reach senior leadership levels.

Read the Book. No Bullsh*t Project: A Project Manager’s guide to successful project leadership. Available on Amazon.

Promote Your Business. Get your brand in front of 8,500+ highly engaged construction leaders and decision-makers with a 51% open rate.